Admin

May 30, 2023

Decoding Sewer Networks through Insights into Wastewater Data

Please see below a translation of the German interview with Brynn Williams published in GWF Wasser written by Dr. Hildegard Lyko.

Brynn Williams, Sales Director of Kando for DACH, about the details.

Decoding Sewer Networks through Insights into Wastewater Data

The wastewater infrastructure and municipal treatment plants are daily confronted with various types and loads of pollutants. In addition to the expected loads for which our treatment plants are designed, elevated concentrations of pollutants can occur in wastewater due to individual events, causing problems in the facilities. Knowing in advance what comes from where and in what quantity to the treatment plant or the receiving waters allows for proactive intervention. The Israeli company Kando processes multiple data sets, including near real-time data from the sewer network using artificial intelligence and machine learning in order to inform utilities on what is coming their way. We spoke with Brynn Williams, Sales Director of Kando for DACH, about the details.

Mr. Williams, the COVID-19 pandemic has also taught the general public that wastewater monitoring can be helpful.

What is the current state of wastewater surveillance in Germany and Europe from your perspective?

Continuous monitoring of sewer networks, where water quality is continuously tracked at strategic points, is currently scarce in Germany and most European countries, in my opinion. What we currently see is that large industrial plants usually have pre-treatment systems for wastewater or even their own treatment plants, as well as their own monitoring points that are regularly checked and compared to the existing discharge permits. Traditional sampling techniques are typically used in these cases. However, what we often don’t see, and what cannot be captured with traditional methods, are wastewater events such as unplanned pollutant inputs from unknown sources, which can occur due to operational issues or disruptions in wastewater treatment. During such events, neither the volume of wastewater discharged nor the pollutant loads are fully recorded. These pollutant inputs may cause corrosion in the facilities, damage the biological wastewater treatment, and ultimately end up in water bodies.

How can these wastewater events be detected?

The wastewater monitoring we carry out aims to map sewer networks as a kind of digital twin. We analyze deviations in wastewater quality to identify dirt loads within the sewer network in real-time and protect the treatment plant. This is done using IoT devices. When an anomaly is detected, the team responsible for pre-treatment and the wastewater treatment plant operator are alerted. In the case of severe contamination that violates applicable guidelines and can impair the wastewater treatment process, an automated sampling for further laboratory analysis is initiated at the respective location. The information obtained from these samples allows for prompt measures to protect the sewer network and the treatment plant from substances that can harm the facilities or affect their operation. Furthermore, these pollutants can be traced back to their source, enabling the treatment plant operator or authorities to contact the responsible party. Artificial intelligence “learns” what wastewater quality is considered “normal” and what is not.

To address the initial question about the current state of wastewater monitoring, it is inadequate in my opinion. However, if we want to protect water bodies and operate wastewater treatment plants efficiently and with minimal disruptions, especially during times of labor shortages, we cannot continue as before. Because what we cannot see, we cannot monitor or optimize. And this is not a question of technologies, as they are already available. Particularly in the field of industrial wastewater treatment, regulatory authorities and treatment plants are currently busy identifying wastewater events and determining their sources to protect the treatment plants and ensure compliance with permits. This process can sometimes take up to eight months.

If an operator or municipality requests such monitoring, how do you proceed?

Firstly, it is essential to understand the needs of the requesting institution. Where are the pain points that motivate facility operators to implement such monitoring? For wastewater associations, it may be a general need to protect the facilities and sewer network from unforeseen, harmful, and potentially costly events, essentially obtaining insurance for their infrastructure. Other clients may have specific problems, such as certain wastewater constituents that a treatment plant operator cannot attribute to a specific source but lead to high operating costs, such as for chemical agents.

At the beginning, we need a complete picture of the sewage network, for example, through GIS data, including the location of access shafts or pumping stations. In addition, we gather information about the structure of the catchment area and the locations of major industrial facilities, partly from publicly available data on company settlements and publicly accessible image data.How do you incorporate the wastewater loads of these industrial facilities, considering that not every company willingly discloses its wastewater data?

We have more than ten years of experience in developing our monitoring system. During this time, we have created so-called “fingerprints” of typical wastewater compositions from many essential industrial sectors (see image). We know what is generally present in the wastewater from different industries such as food production or metal processing, depending o the country where the production facility is located.

With these fingerprints and information about the structure of the sewer network, we already have an idea of possible entry paths and can strategically position the data collectors.What parameters are measured by the AI tool?

With the IoT devices, we measure pH, conductivity, temperature, and oxygen reduction potential in real-time. We also have the same parameters available for the respective industrial and commercial enterprises in the form of the mentioned fingerprints. Additionally, we capture the volume of the effluent. The water quality values are not treated as global standardized datasets; instead, the specific conditions of each country are taken into account. The absolute values of these measurement parameters are not decisive; rather, their temporal changes in conjunction with a historical data set of the system. These form the basis for the machine learning process, which distinguishes between what is “normal” at a specific measurement point and what is not. When an event with high risk is detected, such as high temperatures, the Kando system determines the severity, automatically takes a sample based on ML and AI analysis, and notifies the responsible parties at the initiating operation and at the wastewater treatment plant. The analysis results for the collected sample are input into the AI system, thereby expanding the existing database.

Currently, which groups of substances cannot be considered in such a system, for example, because the analysis is very time-consuming and these substances become too diluted in the wastewater system? As for the IoT components, the goal is not to install a measurement network with many highly specialized or sensitive sensors. That is not our business model, which can perhaps be better explained using the example of ammonia or nitrogen: If there is an outlier in these cases, it is reflected, among other things, in the ORP value. Then one must examine in the laboratory more precisely which substance contributed to this increase. Outliers in the ORP value, for example, can also be caused by elevated heavy metal concentrations. In principle, all substances that have an available analysis method can be measured in the laboratory; it is a question of effort. And water samples can be concentrated, meaning the concentration of a specific substance in the sewer is no longer decisive for measurability.This raises the next question: How dense should the online measurement system be, and how do you decide where to install the IoT units?

As I mentioned before, our long-standing acquired expertise lies in knowing which contaminations are possible at which industrial sites in principle, and where the IoT devices need to be installed to truly capture the influences of specific potential dischargers. Based on this foundation, we create and validate the measurement network and can install important strategic measurement points to learn about the behavior of wastewater quality in this area. This allows us to quickly obtain a general picture of the wastewater network and also determine if and where additional data collectors may be necessary.

Who carries out the monitoring and operates and maintains the components?

In general, we install and operate the technical components, and we are responsible for ensuring the trustworthiness of the data. The best artificial intelligence cannot function well if the input data is not trustworthy. We work closely with the clients, but most of our customers do not want to burden themselves with additional components, maintenance, and upkeep. Typically, the operation of the wastewater monitoring system is funded through license fees paid by a wastewater association or municipality and is carried out by our employees or partner companies.

Measurement data that the operator already collects can be integrated using a specific data framework.

What results does the AI tool provide, and in what form are they made accessible to users?

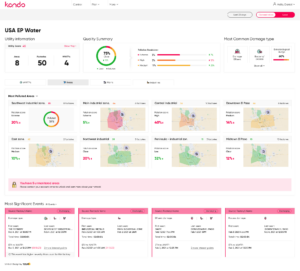

Customers have access to a dashboard that offers several functions: 1) understanding the wastewater quality over time, 2) prioritizing areas to determine which areas require the attention of the pretreatment team, 3) analyzing the discharge behavior of operational pretreatment facilities over time and detecting pollution. The dashboard initially shows what users need to see to assess whether the system is running normally or if there are any significant incidents that require increased attention or actions. The AI-based monitoring system only provides information about the condition of the wastewater network and identifies points with specific incidents but does not include control elements. The system advises and supports the utility company in its operations and data collection for the collection system, enabling the team to take appropriate action.

How easy is it for potential customers, especially engineers and technicians, to trust such a system?

There is generally some skepticism toward software that claims to inform people with years of expertise whether their technical system is functioning properly or not. However, the customer’s employees are not denied any data. All data is available and can be viewed or used for further analysis as needed. The AI tool is primarily designed to make the operators’ work easier and not create additional work for them.

How are the data validated, and who does it?

In addition to the measurement data sent by a data logger, the condition of the component is determined from various measurement and operational data to assess whether it is functioning properly or if maintenance is required, such as cleaning.

The data transmission itself is subject to high-security protocols. The possible source of error remains that the location of a device may not be where the software expects it to be, which needs to be verified. The risk of data transmission being hacked between acquisition and data management systems or data storage is relatively low, in my estimation, because, as mentioned, the system does not control any facilities.

Which institutions should use these results?

Requests for such wastewater monitoring tools come from wastewater companies or network operators, environmental agencies, or even politicians. When there is a potential risk to the environment or public health, political decision-makers must take action to ensure comprehensive clarification; otherwise, they risk losing public trust.

In Germany, we sometimes face the issue that the institution operating the wastewater treatment plant, such as a wastewater association, is not the owner of the connected sewer network. Our AI tool monitors the sewer network to protect the treatment plant from damage and prevent unauthorized pollution in the receiving water bodies. So, who should pay for wastewater monitoring in the sewer network, and who benefits from it? The question of cost allocation is particularly sensitive among the various stakeholders. Ultimately, everyone benefits: the environment and the fee-paying citizens when a treatment plant operates more efficiently, the components have a longer lifespan, and fewer pollutants enter the water bodies.

What future options does this tool offer, such as tracing pollutants, enforcing sanctions, or even supporting law enforcement (drug detection)?

The coronavirus is the most prominent, but not the only pathogen that can be detected early through the wastewater system. Because wastewater monitoring can indicate the spread much earlier than patient tests, proactive measures can be taken for hospitals in the respective area of influence. Similarly, the tracing of drug residues is also possible, and we have already initiated a project for that. However, our main activities lie in wastewater monitoring for facility protection, health protection, and environmental protection.

For more information, please reach out to Brynn Williams directly and book a meeting with him here.

Your wastewater contains the data.

We just need to extract it so that you can optimize your operations.

Contact us and a member of our team will get back to you as soon as possible.